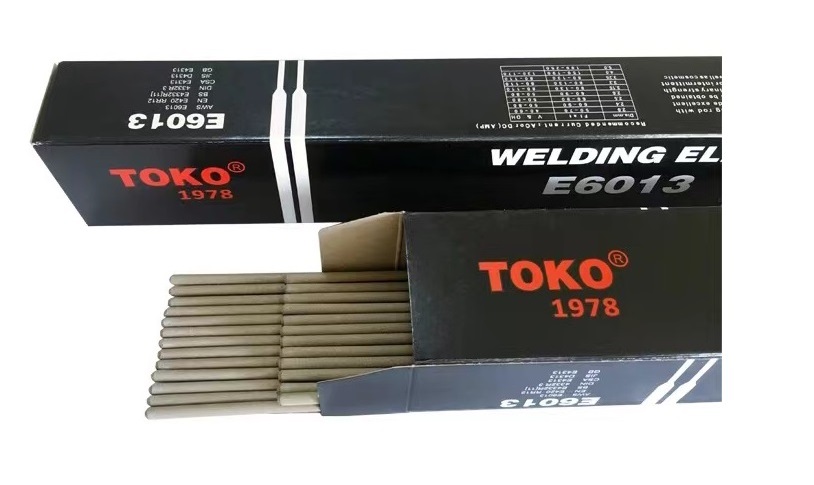

Common Electrode Types

TOKO E6013 electrodes are general-purpose, all-position electrodes suitable for both AC and DC welding. They produce medium penetration with superior weld bead appearance and easy slag removal.

- Excellent Arc Stability: Smooth arc with minimal spatter

- Easy Slag Removal: Self-lifting slag for clean welds

- All Position Welding: Suitable for flat, horizontal, vertical, and overhead positions

- AC/DC Compatibility: Works with both AC and DC power sources

Other common electrodes in our range include:

- E6010/E6011: Deep penetration electrodes for dirty, rusted, or painted metals. E6010 for DCRP only, E6011 for AC and DC.

- E7018/7016: Low hydrogen electrode for high-quality, x-ray welds. Must be kept in dry storage.

TOKO E7018 Low Hydrogen Electrodes

TOKO E7018 electrodes are low hydrogen, iron powder electrodes designed for welding medium carbon and low alloy steels. They produce x-ray quality welds with excellent mechanical properties.

- Low Hydrogen Content: Reduces risk of hydrogen-induced cracking

- Excellent Impact Toughness: Maintains ductility at low temperatures

- Smooth Arc Characteristics: Minimal spatter with easy slag removal

- High Deposition Efficiency: Iron powder coating increases deposition rates

Applications: Pressure vessels, structural steel, shipbuilding, pipelines, and critical fabrication where high-quality welds are required.

TOKO Stainless Steel Electrode E309L-16

TOKO E309L-16 electrodes are designed for welding dissimilar metals and joining stainless steel to mild steel. The "L" designation indicates low carbon content for maximum corrosion resistance.

- Dissimilar Metal Welding: Ideal for joining stainless to carbon steel

- Low Carbon Content: Reduces carbide precipitation and maintains corrosion resistance

- All Position Capability: Suitable for welding in all positions

- Easy Arc Starting: Smooth, stable arc with excellent wetting action

Other common electrodes in our range include:

- EE308L/E312L/E316L: Deep penetration electrodes for dirty, rusted, or painted metals.

- Typical Applications: Overlay welding, joining dissimilar stainless grades, and repair of castings.

TOKO Auto Welding Flux

TOKO Auto Welding Flux is specifically formulated for submerged arc welding (SAW) applications. It provides stable arc characteristics, excellent bead appearance, and easy slag removal.

- High Deposition Rates: Increases productivity in automated welding

- Excellent Weld Bead Profile: Smooth, uniform weld appearance

- Easy Slag Removal: Self-detaching slag reduces cleanup time

- Consistent Performance: Batch-to-batch uniformity ensures reliable results

Recommended Applications: Longitudinal and circumferential seams in pipe manufacturing, structural beam fabrication, pressure vessel welding, and heavy plate joining.

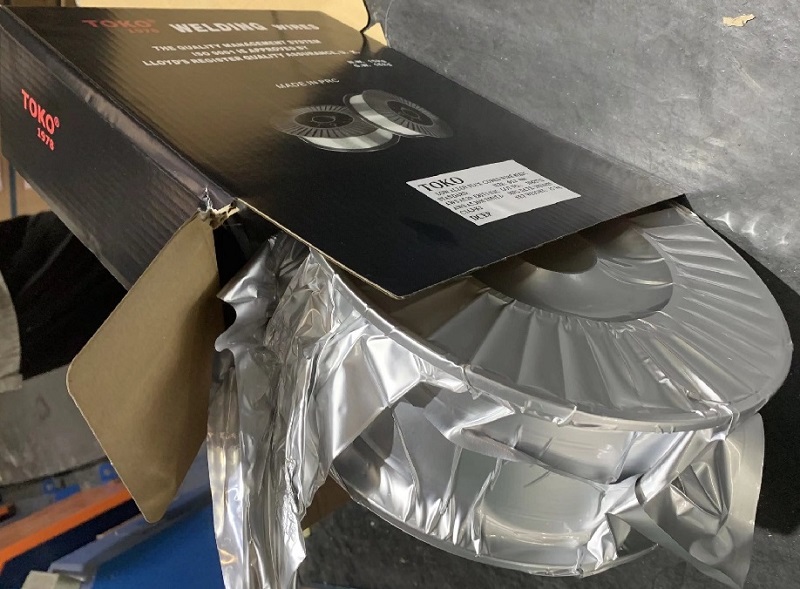

Welding Wires

Aluminum Welding Wires

TOKO ER4043 aluminum welding wire is a general-purpose alloy containing 5% silicon, suitable for welding 6XXX series aluminum alloys.

- ER4043: For 6061, 6063 alloys - excellent fluidity

- ER5356: For 5XXX series - higher strength

- ER5183: Marine grade - superior corrosion resistance

TIG Welding Wires

TOKO copper coated welding wire for welding in gas shielding atmospheres. Suitable for welding unalloyed and low alloyed construction steels.

SFA/AWS A5.28 ER 80S-G

- Copper coating for smooth feedability

- Low spatter generation

- Excellent bead appearance

- Consistent mechanical properties

Flux Cored Welding Wires

TOKO E71T-1C flux cored wire offers higher deposition rates and deeper penetration compared to solid wires.

- E71T-1C: CO2 gas shielded, all position

- E71T-5C: Basic slag system, low hydroge

- E71T-GS: Self-shielded, outdoor use

- E81T1-K2C: -60°C, High-strength wire

Application Materials Compatibility

| Base Materials & Description | DIN, AISI | EN | Recommended TOKO Product |

|---|---|---|---|

| Unalloyed structural steels | St 33 to St 60.2 | 10025 | E6013, E7018, ER70S-6 |

| Fine-grained structural steels | St E 255 to St E 355 | 10025-4 | E7018, E71T-1C, E71T-5C |

| Boiler and pressure vessel plate | W St E 25 to W St E 355 | 10028-2 | E7018, E71T-5C, E81T1-K2C |

| Pipeline steels | HI, H II, 17Mn4, 19Mn5 | 10028-2 | E6010, E7018, E81T1-K2C |

| Shipbuilding steels | St 35 to St 52.4 | 10225 | E7018, E71T-5C, ER80S-G |

| Austenitic stainless steels | 304, 304L, 316, 316L | 1.4301, 1.4404 | E308L-16, E316L-16, E312L-16 |