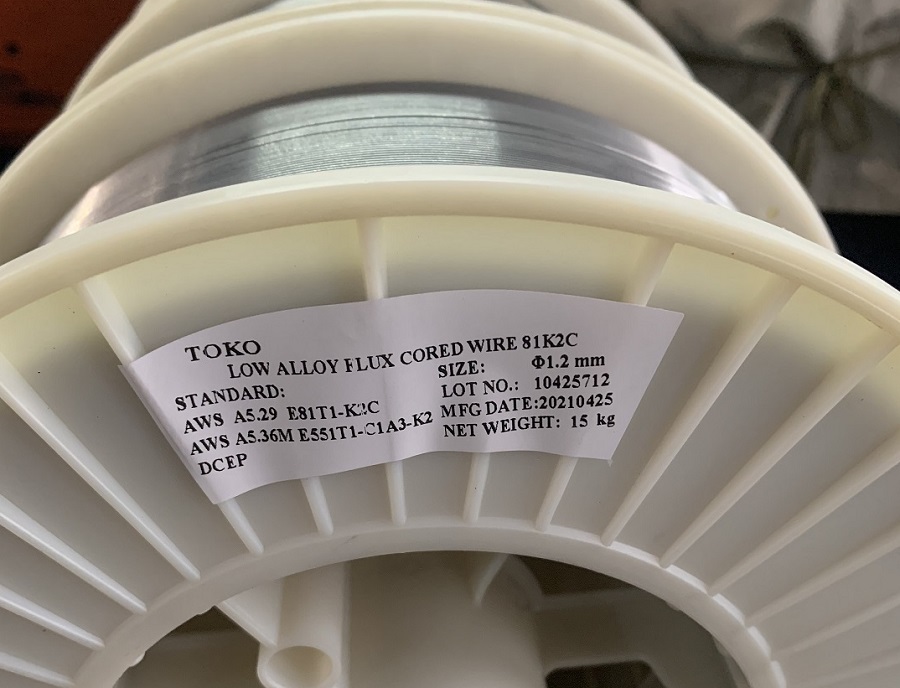

What's features of TOKO AWS A5.29 E81T1-K2C flux cored welding wire?

TOKO AWS A5.29 E81T1-K2C flux-cored wire is a high-strength, low-alloy (HSLA) wire designed for demanding structural applications requiring excellent toughness, particularly at low temperatures. Here's a breakdown of its key features based on the AWS classification and typical performance:

1, AWS Classification (E81T1-K2C):

-

81: Minimum tensile strength of the deposited weld metal is 81,000 psi (560 MPa).

-

T1: Tubular (flux-cored) wire designed for use with CO₂ or Argon-CO₂ shielding gas mixtures. Indicates specific operating characteristics (spray transfer, good slag coverage, positional capability).

-

K2: Chemical composition designation. Specifically denotes weld metal containing:

-

Nickel (Ni): 1.50 - 2.50% (Key for low-temperature toughness).

-

Molybdenum (Mo): 0.15 - 0.65% (Enhances strength and toughness).

-

-

C: Suffix indicating the weld metal meets supplemental "Improved Toughness" requirements. This typically means it guarantees significantly higher impact values at very low temperatures (often down to -40°C / -40°F or lower) compared to the base K2 classification.

2, Key Features & Performance Characteristics:

-

High Strength: Delivers weld metal with a minimum tensile strength of 81 ksi (560 MPa), suitable for high-stress structural applications.

-

Exceptional Low-Temperature Toughness: The combination of Nickel (Ni) and the "C" suffix is the standout feature. This wire is specifically engineered to provide outstanding impact toughness (Charpy V-Notch values) at temperatures as low as -40°C (-40°F) and often down to -60°C (-76°F). This makes it ideal for:

-

Offshore structures

-

Arctic pipelines & equipment

-

Mining equipment in cold climates

-

Bridges in cold regions

-

Pressure vessels operating at low temperatures

-

Critical structural components requiring high fracture resistance.

-

-

Good Crack Resistance: The composition (Ni, Mo) and flux system generally promote good resistance to solidification cracking and hydrogen-induced cracking (HIC), especially when used with proper procedures (preheat, low hydrogen practices).

-

All-Position Welding (T1 Classification): Suitable for welding in all positions (Flat, Horizontal, Vertical-Up, Vertical-Down, Overhead) due to its fast-freezing slag system.

-

Good Arc Stability & Bead Appearance: Typically provides a smooth, stable arc with low spatter and a clean, uniform bead profile under the recommended conditions.

-

Easy Slag Removal: The T1 slag system is designed to be self-releasing or easily removable, improving productivity.

-

Higher Deposition Rates: Like most FCAW wires, it generally offers higher deposition rates compared to SMAW (stick welding).

-

Shielding Gas: Requires 100% CO₂ or Argon-CO₂ mixtures (typically 75-95% Ar / 5-25% CO₂). Argon mixtures usually provide a smoother arc, less spatter, and slightly better low-temperature toughness than pure CO₂.

3, Typical Applications:

-

Welding high-strength, low-alloy steels (ASTM A514, A517, A709 Gr 100/100W, A871, etc.).

-

Critical structures subjected to dynamic loading and low temperatures.

-

Offshore platforms, shipbuilding (high-strength hulls), and pipelines in cold environments.

-

Heavy mining, earthmoving, and construction equipment frames and booms.

-

Pressure vessels and storage tanks requiring low-temperature service.

-

Bridge components and other infrastructure in cold climates.

In Summary: TOKO E81T1-K2C is a premium, gas-shielded (CO₂ or Ar/CO₂), flux-cored wire delivering 81 ksi tensile strength with a primary focus on exceptional low-temperature toughness down to -40°C (-40°F) or lower, achieved through its Nickel-Molybdenum alloy content (K2) and meeting supplemental "Improved Toughness" ("C") requirements. It offers good all-position capability, arc performance, and productivity for welding demanding HSLA steels in critical, cold-service applications. Always consult the specific manufacturer's datasheet for detailed operating parameters and performance guarantees.

The information contained or otherwise referenced herein is presented only as “typical” without guarantee or warranty, and TOKO Corporation expressly disclaims any liability incurred from any reliance thereon. Typical data and Test results for mechanical properties, deposit or electrode composition and other properties were obtained from a weld produced and tested according to prescribed standards, and should not be assumed to be the expected results in a particular application or weldment. Actual results will vary depending on many factors, including, but not limited to, weld procedure, plate chemistry and temperature,weldment design and fabrication methods. Users are cautioned to confirm by qualification testing, or other appropriate means, the suitability of any welding consumable and procedure before use in the intended application.