Achieving consistent, high-quality welds with TOKO brand consumables requires understanding proper usage techniques to prevent common defects. This guide outlines best practices for maximizing performance in your daily production.

1Pre-Welding Preparation (The Foundation)

What it is: Proper preparation before welding begins is critical to prevent defects at their source.

Key Preparation Steps:

- Consumable Selection: Ensure you're using the right TOKO electrode or wire for your base material and application requirements.

- Proper Storage: Store TOKO consumables correctly - low-hydrogen electrodes in heated ovens, all consumables in dry, temperature-controlled environments.

- Joint Preparation: Clean all surfaces thoroughly to remove rust, oil, grease, and moisture that cause porosity and lack of fusion.

- Equipment Check: Verify proper grounding, gas flow rates, and equipment condition before starting.

TOKO-Specific Advantages:

- Comprehensive Product Range: TOKO offers specialized consumables for various materials and applications.

- Quality Packaging: Our packaging is designed to protect consumables from moisture and damage during storage.

- Technical Data Sheets: Detailed specifications help you select the perfect product for your needs.

2During Welding (Execution with Precision)

What it is: Proper technique and parameter control during the welding process.

Critical Execution Factors:

- Follow WPS: Adhere to the qualified Welding Procedure Specification for all parameters.

- Parameter Control: Maintain correct amperage, voltage, and travel speed for your specific TOKO consumable.

- Proper Technique: Use consistent work and travel angles, arc length, and manipulation methods.

- Interpass Cleaning: Remove all slag between passes to prevent inclusions in multi-pass welds.

TOKO Performance Benefits:

- Superior Arc Stability: TOKO consumables provide smooth, consistent arc performance for better control.

- Easy Slag Removal: Formulated slag systems peel off easily, improving productivity.

- Optimal Bead Profile: Designed to produce aesthetically pleasing, consistent weld beads.

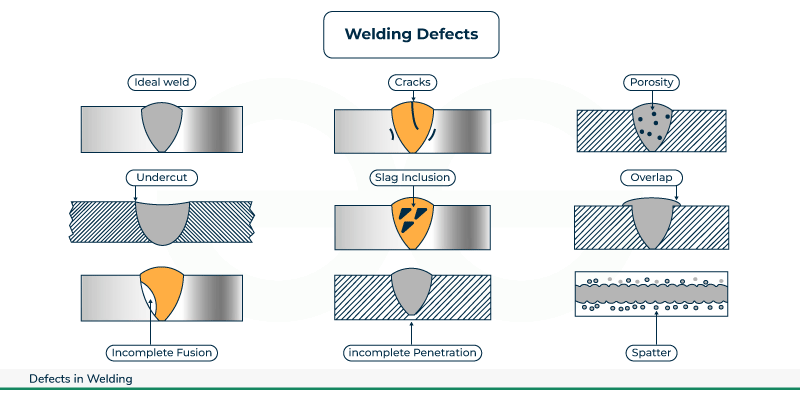

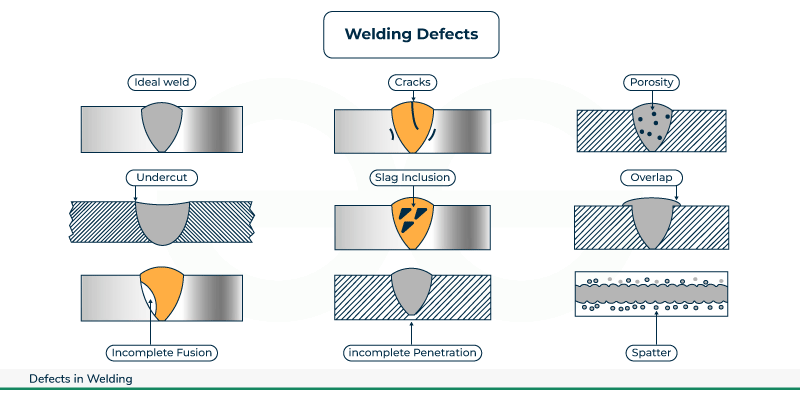

3Addressing Common Welding Defects

What it is: Proactive identification and prevention of specific welding defects.

Common Defects & Prevention:

- Porosity: Caused by moisture, contamination, or improper gas shielding. Prevent with proper storage, cleaning, and gas flow.

- Lack of Fusion: Results from low amperage, incorrect angle, or excessive travel speed. Use proper parameters and technique.

- Cracking: Hydrogen-induced or hot cracking from restraint, moisture, or rapid cooling. Control hydrogen sources and use preheat when needed.

- Undercut: Caused by excessive amperage or travel speed. Adjust parameters and technique.

TOKO Defect Prevention Features:

- Low-Hydrogen Formulations: Specifically designed to minimize hydrogen-induced cracking.

- Controlled Moisture Content: Manufacturing processes ensure minimal moisture in flux and coatings.

- Consistent Performance: Batch-to-batch consistency reduces variability and unexpected defects.

4TOKO-Specific Advantages for Quality Welding

What it is: Unique benefits of TOKO welding consumables that help prevent defects.

TOKO Quality Features:

- Superior Arc Stability: Consistent arc characteristics reduce operator variability and defects.

- Excellent Weld Metal Properties: Optimal mechanical properties and chemical composition for various applications.

- Minimal Spatter: Formulations designed to reduce spatter, saving cleanup time and improving appearance.

- Easy Slag Removal: Slag systems that peel off easily, reducing the risk of slag inclusions.

- All-Position Capability: Many TOKO consumables are designed for all-position welding with consistent results.

Maximizing TOKO Performance:

- Consult Technical Data: Always refer to TOKO's technical sheets for recommended parameters.

- Proper Storage: Maintain consumables according to TOKO's storage recommendations.

- Training: Utilize TOKO's technical support and training resources for optimal results.

5Summary for Daily Production Success

What it is: Key takeaways for implementing TOKO welding consumables in your daily production.

Essential Practices:

- Respect the Consumable: Store TOKO electrodes and wires properly - baking is mandatory for low-hydrogen types.

- Clean, Clean, Clean: A contaminant-free joint is fundamental to defect prevention.

- Follow the Recipe: Adhere to WPS parameters for amperage, voltage, and gas settings.

- Master Your Technique: Consistent travel speed, arc length, and angle are critical.

- Inspect As You Go: Clean between passes and visually check each bead before proceeding.

The TOKO Advantage in Your Production:

- Reduced Defect Rates: Consistent quality leads to fewer rejects and rework.

- Increased Productivity: Easy handling and optimal performance save time and labor.

- Lower Total Cost: Reduced defects and increased efficiency improve your bottom line.

TOKO Advantages for Defect-Free Welding

-

Consistent Quality: TOKO's manufacturing processes ensure batch-to-batch consistency for predictable results.

-

Technical Support: Our expert team is available to help select the right products and troubleshoot your process.

-

Comprehensive Range: From basic mild steel to specialized alloys, TOKO has consumables for every application.

-

Proven Performance: Decades of experience and continuous improvement ensure reliable performance.

-

Global Standards: TOKO products meet or exceed international quality standards for welding consumables.

-

Value Optimization: Our consumables are designed to deliver the best balance of performance and cost-effectiveness.

Conclusion

Successfully implementing TOKO welding consumables in your daily production requires a systematic approach to preparation, execution, and quality control. By combining proper technique with TOKO's high-quality products, you can achieve consistent, defect-free welds with maximum productivity.

Don't let welding defects disrupt your operations and compromise quality. Contact TOKO today to find the perfect welding solution for your specific application and receive expert guidance on implementation.

Disclaimer: The information contained or otherwise referenced herein is presented only as "typical" without guarantee or warranty,

and TOKO Corporation expressly disclaims any liability incurred from any reliance thereon. Typical data and Test results for mechanical properties,

deposit or electrode composition and other properties were obtained from a weld produced and tested according to prescribed standards, and should not

be assumed to be the expected results in a particular application or weldment. Actual results will vary depending on many factors, including, but not

limited to weld procedure, plate chemistry and temperature, weldment design and fabrication methods. Users are cautioned to confirm by qualification

testing, or other appropriate means, the suitability of any welding consumable and procedure before use in the intended application.