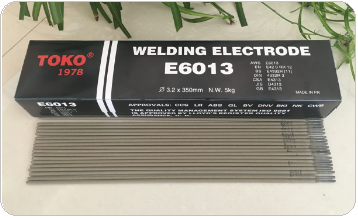

WELDING ELECTRODE

TOKO brand welding consumables are

original from Japan and has JVC production base in China, as a professional producer

and supplier of Welding electrodes and Welding wire since 1978.

TOKO welding consumables including: 1) Carbon steel welding electrode and welding wire; 2) Stainless steel welding electrode and welding wire; 3) Alloy materials welding electrode and welding wire and etc.

Electrode Identification

Arc welding electrodes are identified

using the A.W.S, (American Welding Society) numbering system and are made in

sizes from 1/16 to 5/16. An example would be a welding rod identified as an

1/8" E6013 electrode.

The electrode is 1/8" in diameter

The "E" stands for arc welding electrode.

Next will be either a 4 or 5 digit number stamped on the electrode. The first two numbers of a 4 digit number and the first 3 digits of a 5 digit number indicate the minimum tensile strength (in thousands of pounds per square inch) of the weld that the rod will produce, stress relieved. Examples would be as follows:

E60xx would have a tensile strength of 60,000 psi E110XX would be 110,000 psi

The next to last digit indicates the position the electrode can be used in

The electrode is 1/8" in diameter

The "E" stands for arc welding electrode.

Next will be either a 4 or 5 digit number stamped on the electrode. The first two numbers of a 4 digit number and the first 3 digits of a 5 digit number indicate the minimum tensile strength (in thousands of pounds per square inch) of the weld that the rod will produce, stress relieved. Examples would be as follows:

E60xx would have a tensile strength of 60,000 psi E110XX would be 110,000 psi

The next to last digit indicates the position the electrode can be used in

- EXX1X is for use in all positions

- EXX2X is for use in flat and horizontal positions

- EXX3X is for flat welding

TOKO Electrodes And Currents Used

- EXX10 DC+ (DC reverse or DCRP) electrode positive.

- EXX11 AC or DC- (DC straight or DCSP) electrode negative.

- EXX12 AC or DC-

- EXX13 AC, DC- or DC+

- EXX14 AC, DC- or DC+

- EXX15 DC+

- EXX16 AC or DC+

- EXX18 AC, DC- or DC+

- EXX20 AC ,DC- or DC+

- EXX24 AC, DC- or DC+

- EXX27 AC, DC- or DC+

- EXX28 AC or DC+

TOKO Electrode Size And AMPS Used

The following will serve as a basic

guide of the amp range that can be used for different size electrodes. Note

that these ratings can be different between various electrode manufactures

for the same size rod. Also the type coating on the electrode could effect

the amperage range. When possible, check the manufactures info of the

electrode you will be using for their recommended amperage settings.

Note! The

thicker the material to be welded, the higher the current needed and the

larger the electrode needed.

| Electrode Diameter (Thickness) | AMP Range | Plate |

|---|---|---|

| 1/16" | 20 - 40 | UP TO 3/16" |

| 3/32" | 40 - 125 | UP TO 1/4" |

| 1/8 | 75 - 185 | OVER 1/8" |

| 5/32" | 105 - 250 | OVER 1/4" |

| 3/16" | 140 - 305 | OVER 3/8" |

| 1/4" | 210 - 430 | OVER 3/8" |

| 5/16" | 275 - 450 | OVER 1/2" |

WELDING ELECTRODE CLASSIFICATIONS

Mild Steel Coated Electrodes

- E7018-1 Indicates that this is an electrode

- E for Electrode

- 70 Indicates how strong this electrode is when welded. Measured in thousands of pounds per square inch.

- 1 Indicates in what welding positions it can be used.

- 8 Indicates the coating, penetration, and current type used. (See Classification Table below)

SOME ELECTRODE TYPES

This section will briefly describe

four electrodes that are commonly used for maintenance and repair welding of

mild steel. There are many other electrodes available for the welding of

other kinds of metals. Check with your local welding supply dealer for the

electrode that should be used for the metal you want to weld.

- E6010 This electrode is used for all position welding using DCRP. It produces a deep penetrating weld and works well on dirty, rusted, or painted metals

- E6011 This electrode has the same characteristics of the E6010, but can be used with AC and DC currents.

- E6013 This electrode can be used with AC and DC currents. It produces a medium penetrating weld with a superior weld bead appearance.

- E7018 This electrode is known as a low hydrogen electrode and can be used with AC or DC. The coating on the electrode has a low moisture content that reduces the introduction of hydrogen into the weld. The electrode can produce welds of x-ray quality with medium penetration. (Note, this electrode must be kept dry. If it gets wet, it must be dried in a rod oven before use.)

WELDING WIRES FOR MAG (CO2) WELDING

Classification

E71T-1 (FCAW-G): Highest deposition rates out-of-position.

E71T-8 (FCAW-S): Highest deposition rates out-of-position without a shielding gas.

E70T-4 (FCAW-S): Highest deposition rates in the flat position.

E70T-1 (FCAW-G): Highest deposition rates in the flat position with Charpy properties.

E71T-14 (FCAW-S): Fastest travel speed on galvanized and coated steels.

E70T-5 (FCAW-G): Fastest way to weld hard-to-weld steels.

E71T-8 (FCAW-S): Highest deposition rates out-of-position without a shielding gas.

E70T-4 (FCAW-S): Highest deposition rates in the flat position.

E70T-1 (FCAW-G): Highest deposition rates in the flat position with Charpy properties.

E71T-14 (FCAW-S): Fastest travel speed on galvanized and coated steels.

E70T-5 (FCAW-G): Fastest way to weld hard-to-weld steels.

ER70S-6 (CO2 Solid Wire)

Description and Application

TOKO solid copper coated welding

wire for welding in gas shielding atmospheres. Slightly higher silicon and

manganese alloyed than Euro Tig 2. The higher contains of silicon and

manganese increase the yield stress and tensile strength of weld metal. The

high silicon content promotes a low sensitivity to surface impurities and

contributes to smooth weld. Suitable for welding unalloyed and low alloyed

construction steels with tensile strength below 640N/mm2 like boiler plate,

fine grained steels, pipe steels, shipbuilding steels and cast steels.

| Base materials & Description | DIN, AISI | EN |

|---|---|---|

| Unalloyed steels | St 33 to St 60.2 | 10025 |

| Fine-grained steels | St E 255 to St E 355 | - |

| Boiler and vessel plate | W St E 25 to W St E 355 | - |

| Pipe steels | HI,H II,17Mn4,19Mn5 | 10028-2 |

| Shipbuilding steels | St 35 to St 52.4 | - |

| E St E 210.7 to St E 360.7 | - | |

| A,B,D,E | 10025 |

Description and Application

TOKO WELDING WIRE FOR TIG

SFA/AWS A5.28 ER 80S-G

CHARACTERISTICS:

EURO 80SG is a copper coated wire for TIG welding of 1Cr1/2Mo steels.| Typical all weld metal chemical composition element | C | Mn | Si | S | P | Cr | Mo |

|---|---|---|---|---|---|---|---|

| % | 0.12 | 1.20 | 0.80 | 0.025 | 0.025 | 1.50 | 0.60 |