TOKO maintains the highest quality standards with ISO 9001:2015 certified production facilities and comprehensive quality management systems for welding electrodes, wires, and flux.

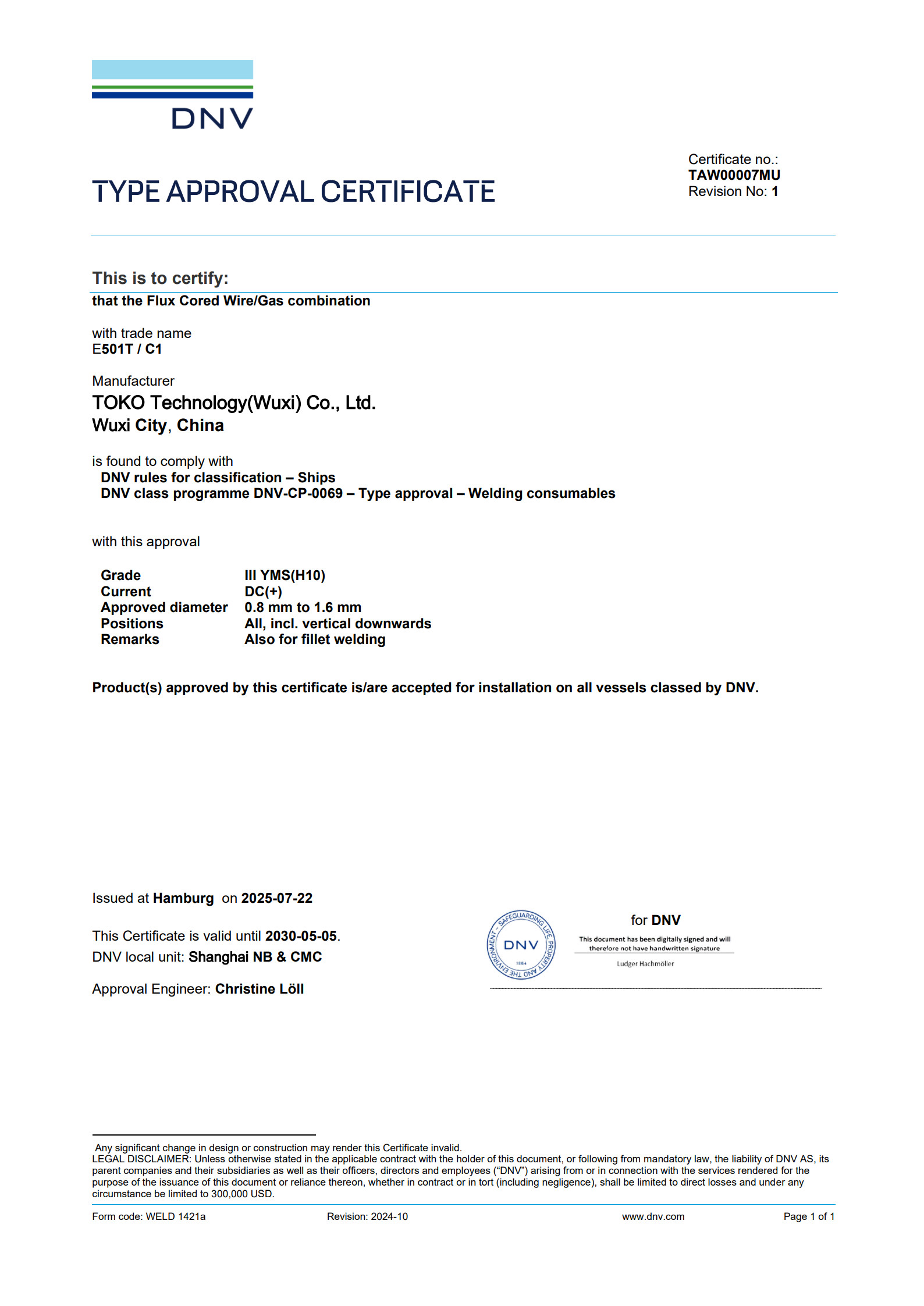

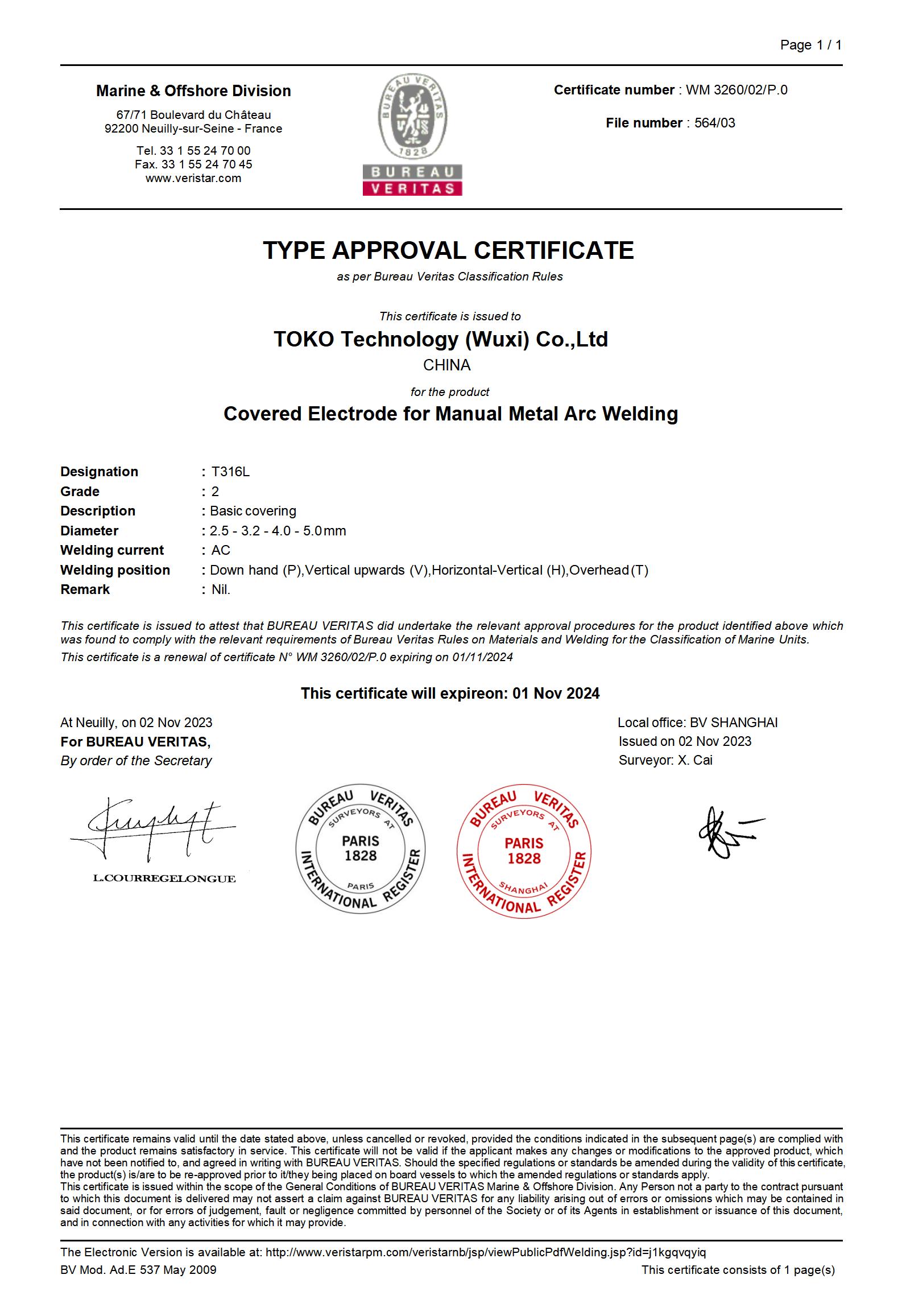

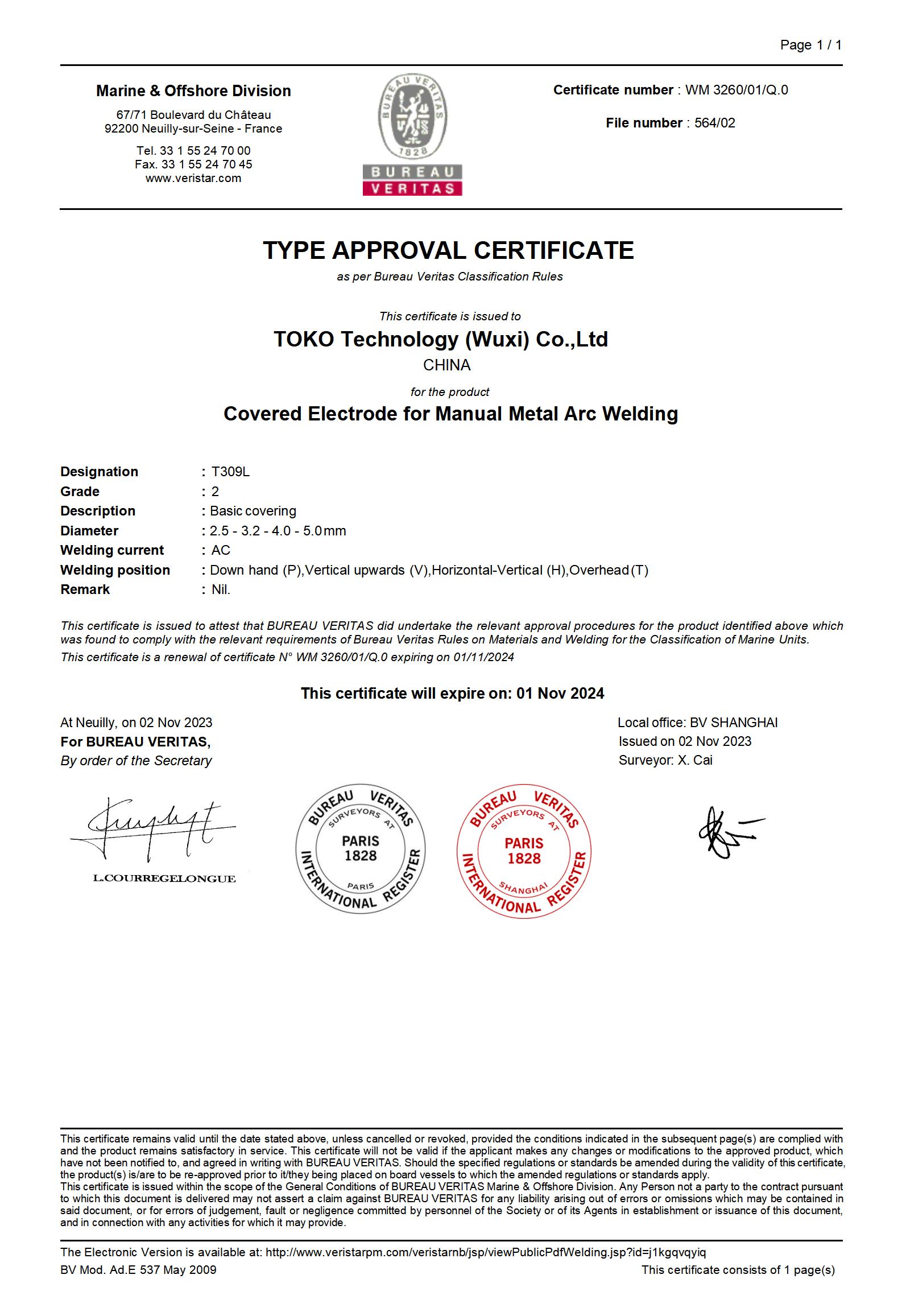

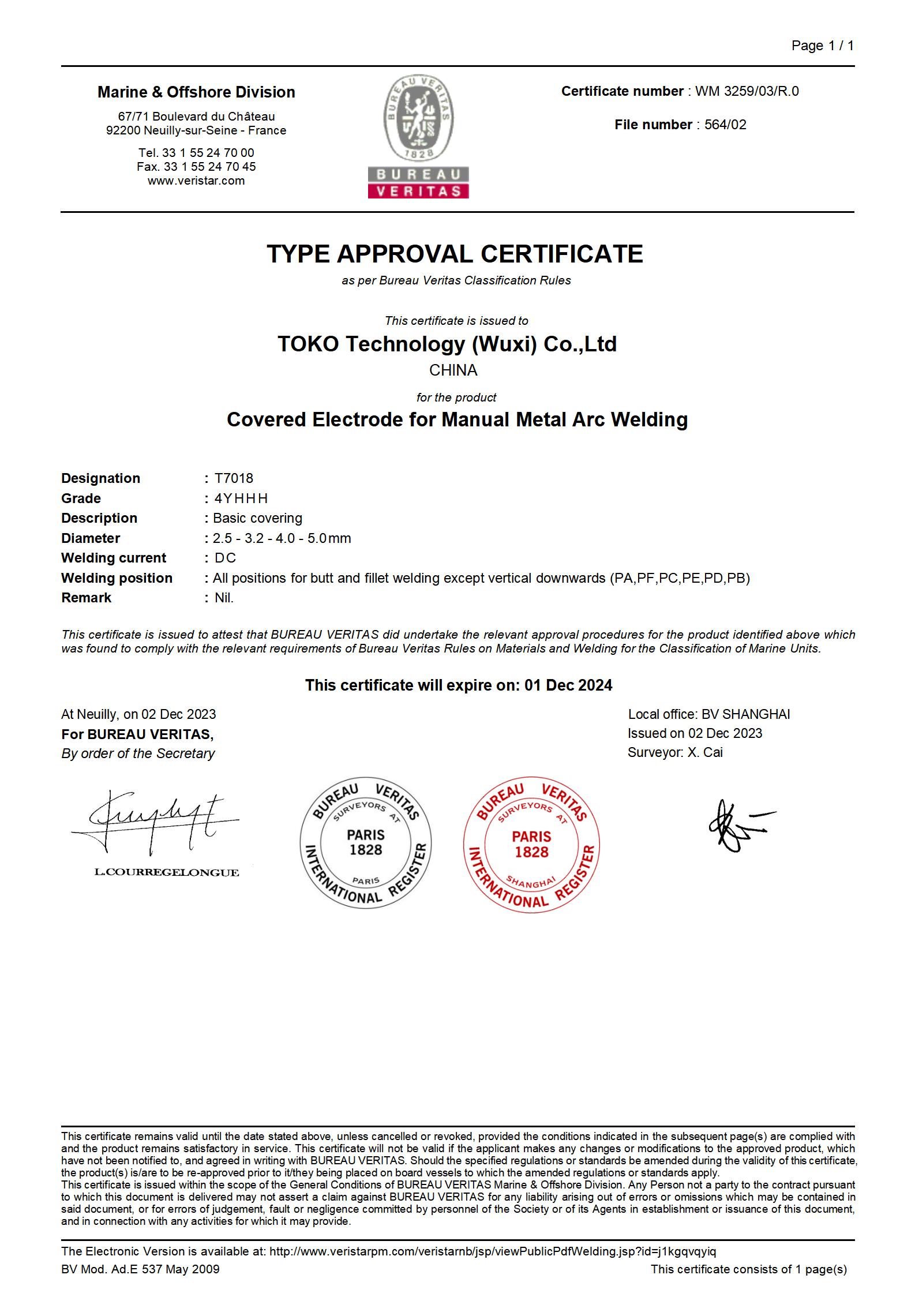

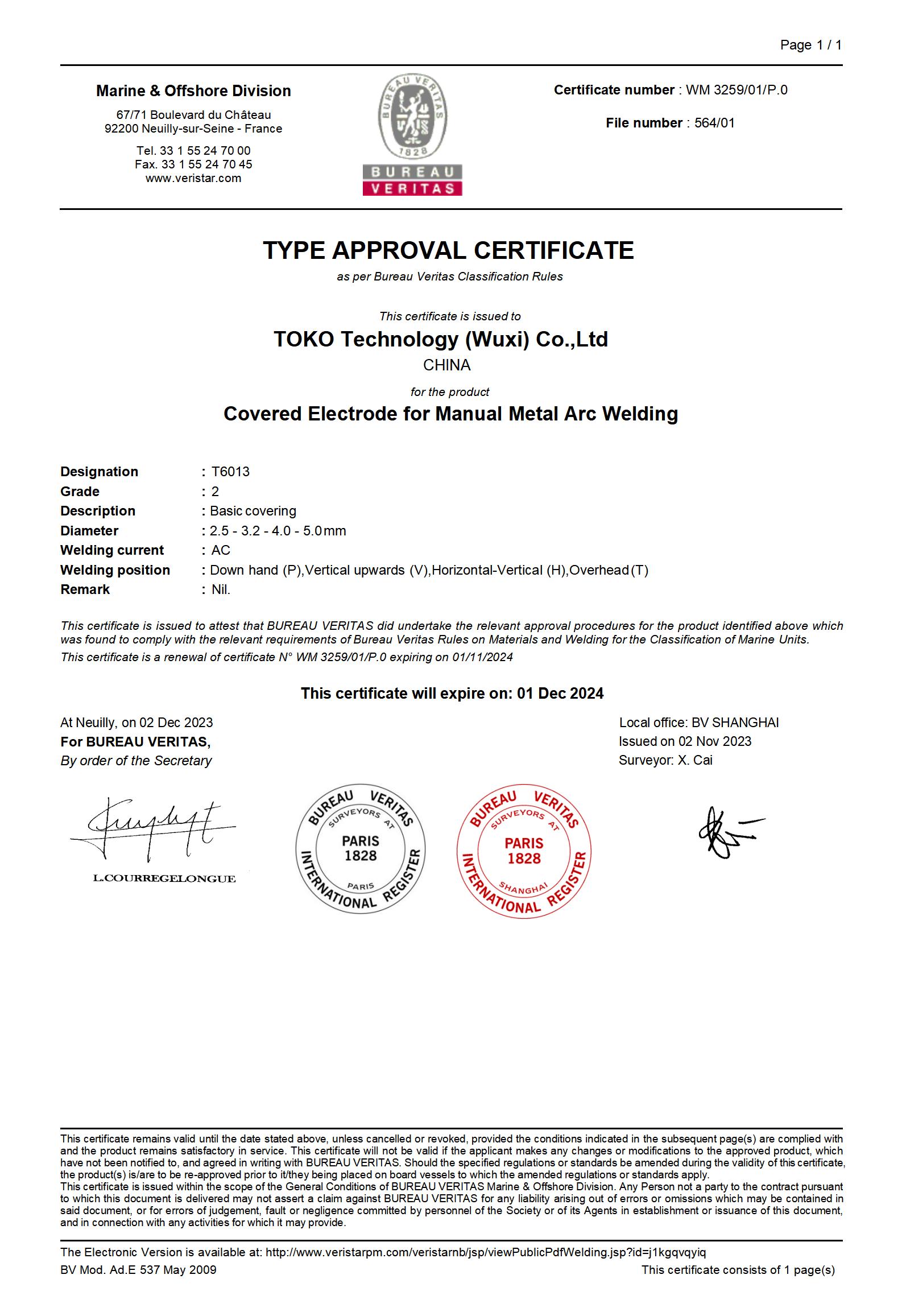

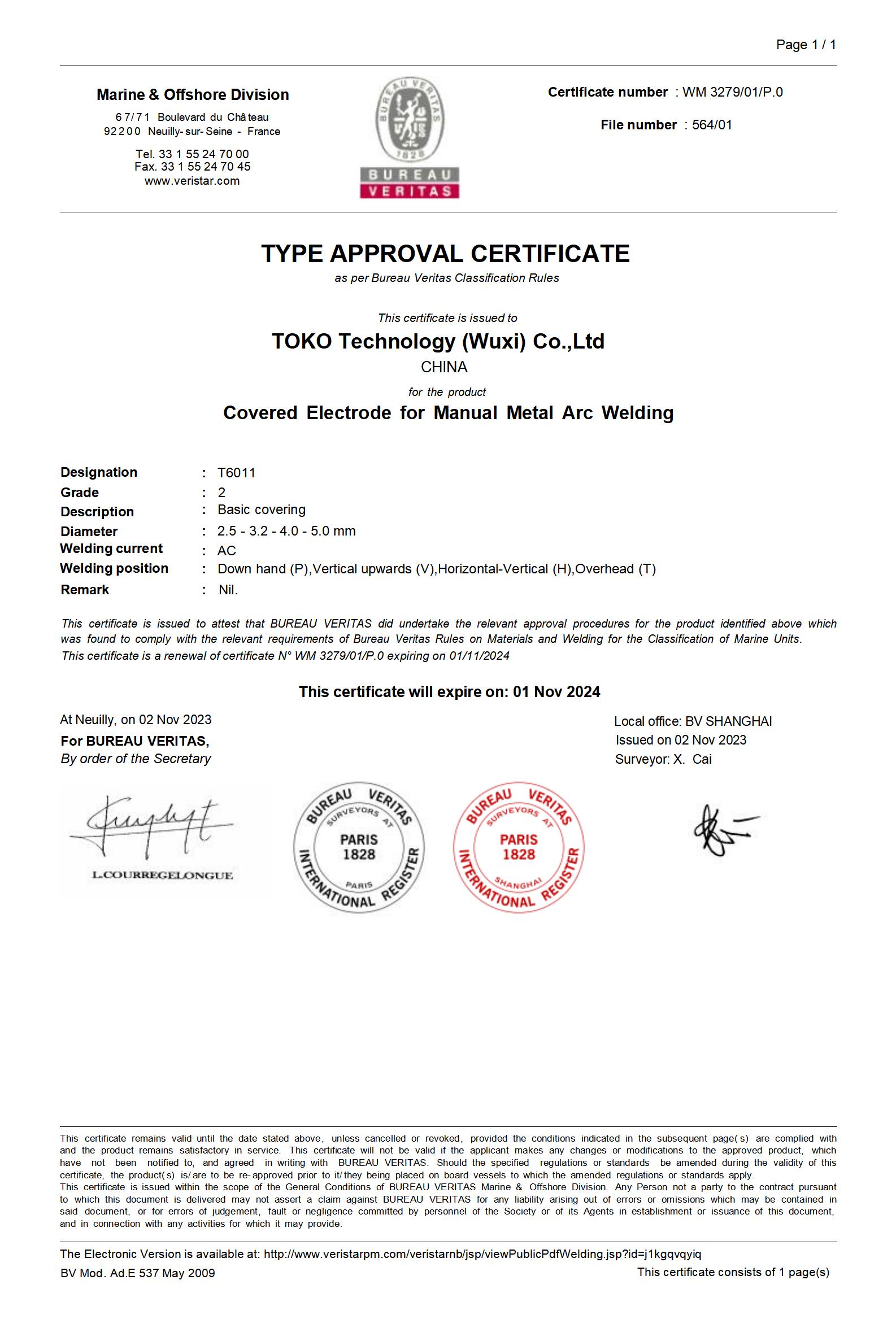

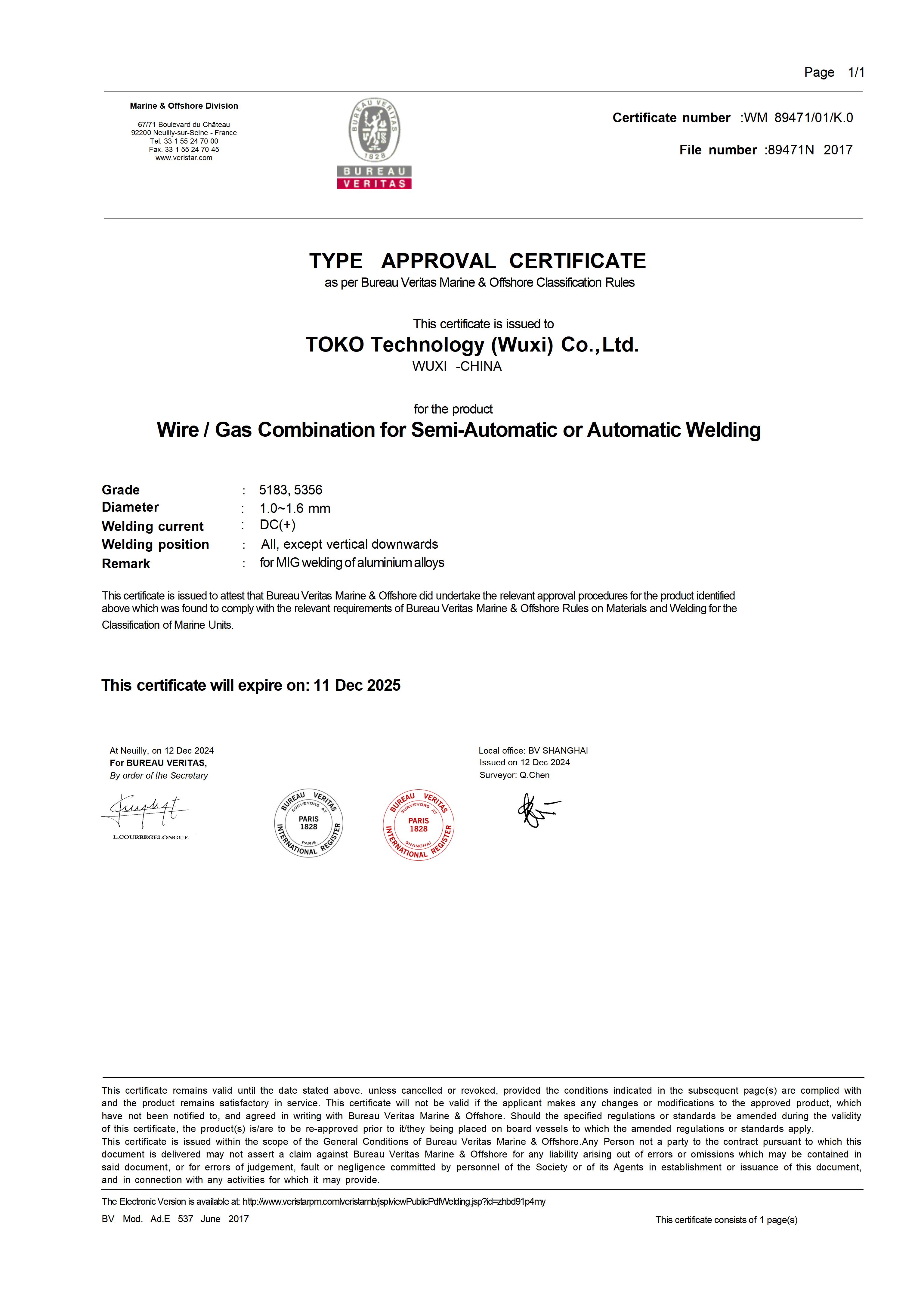

TOKO welding electrodes have earned prestigious Bureau Veritas (BV) certification across multiple product lines, providing independent third-party validation of our quality standards and manufacturing excellence. Our welding consumables meet rigorous international standards for performance and reliability.

At TOKO, we've established a comprehensive quality management system that ensures our welding processes, products, and services are designed, developed, and delivered with meticulous attention to detail. We continuously improve our processes and products by systematically collecting customer feedback, implementing corrective and preventive actions, and fostering a culture of continuous learning and innovation. Our quality policy emphasizes defect prevention rather than detection, ensuring consistent product excellence.

We continuously update TOKO quality standards and strengthen our quality assurance structure across all manufacturing facilities. Through rigorous quality control measures, we maintain ISO certification standards and provide exceptional quality support to satisfy our customers' welding application requirements across industries including shipbuilding, LNG storage, offshore engineering, and heavy industry.

BV Certifications: Independent Quality Validation for Welding Consumables

Our ISO 9001:2015 certification demonstrates our commitment to consistent quality and continuous improvement. This internationally recognized standard ensures that our quality management system addresses all aspects of our operations, from product design and development to manufacturing, testing, and customer service. The certification covers our complete range of welding consumables including stick electrodes, flux-cored wires, solid wires, and submerged arc welding flux.

Ongoing process optimization, quality enhancement initiatives, and systematic review of quality performance metrics.

Comprehensive material testing, quality control protocols, and performance validation for all welding consumables.

Highly trained quality professionals dedicated to maintaining and exceeding international quality standards.

Comprehensive quality guarantee with traceability and documentation for all certified welding products.