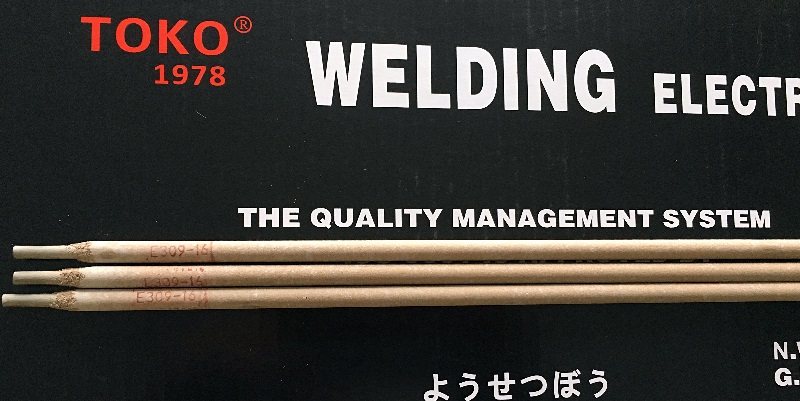

TOKO AWS A5.4 E309L Welding Electrode

TOKO E309L Stainless Steel, All-Position Electrode for High-temperature equipment (furnaces, exhaust systems), is used for welding austenitic stainless steels to other stainless-steel types. It is also used for welding of stainless steel to low alloy steel, carbon steel, mild steel and cast Steel.

Key Advantages

- AWS A5.4 Compliance: Certified stainless steel electrode for high-temperature applications.

- Dissimilar Metal Welding: Ideal for joining stainless steel to carbon steel and other alloys.

- High-Temperature Resistance: Excellent performance in furnace and exhaust system applications.

- All-Position Capability: Suitable for welding in all positions.

- Low Carbon Content: Minimizes sensitization in high-temperature environments.

Classification & Specification

- AWS Classification: Compliant with AWS A5.4 E309L standards.

- Material Compatibility: Austenitic stainless steels, carbon steel, low alloy steel, and cast steel.

- Specialty: Designed for dissimilar metal welding and high-temperature applications.

Common Applications

- High-temperature equipment (furnaces, exhaust systems)

- Dissimilar metal welding (stainless to carbon steel)

- Petrochemical industry equipment

- Power generation applications

- Food processing equipment

- Cladding/overlaying carbon steel for corrosion resistance

Technical Specifications

Chemical Composition (Typical Weld Metal)

| Element | Content (%) |

|---|---|

| Chromium (Cr) | 23-25% |

| Nickel (Ni) | 12-14% |

| Carbon (C) | ≤0.03% |

| Manganese (Mn) | Trace amounts |

| Silicon (Si) | Trace amounts |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | ~620 MPa (90 ksi) |

| Elongation | 35-40% |

| Corrosion Resistance | Superior in high-temperature environments |

| Magnetic Properties | Non-magnetic (austenitic structure) |

Operating Characteristics

- Polarity: DC+ (direct current electrode positive).

- Preheat/Interpass Temperature: Generally unnecessary for thin sections; maintain ≤150°C (300°F) for thick materials.

- Post-Weld Treatment: Stress relief annealing may be required for critical applications.

- Storage: Keep in dry conditions to prevent moisture pickup.

TOKO-Specific Features

- Arc Stability: TOKO electrodes are known for smooth arc characteristics and minimal spatter.

- Slag Removal: Easy slag detachment improves weld efficiency.

- Certifications: Meets international standards (e.g., ISO, EN) for quality assurance.

- Weld Quality: Produces high-quality welds with excellent appearance and performance.

Technical Documentation

✅ For specific guidance and welding parameters, refer to TOKO's technical datasheets and welding procedure specifications.