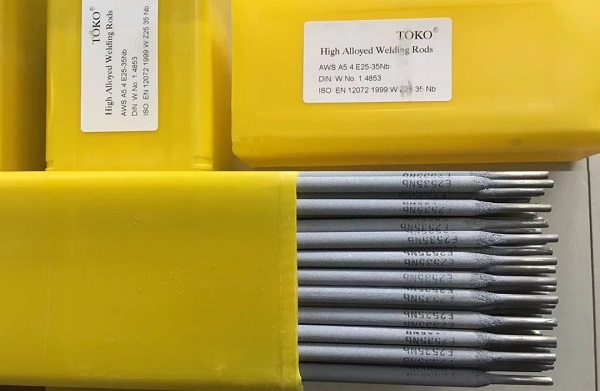

TOKO 2535Nb NiCr Alloy Welding Rods

TOKO E2535Nb is nickel-chromium-based Alloy Welding rods | designed for specialized welding applications requiring exceptional resistance to high temperatures, oxidation, and corrosion. These rods are engineered for joining and repairing nickel-chromium alloys, particularly in demanding environments such as power plants, petrochemical facilities, and high-temperature industrial equipment.

Key Advantages

- High-Temperature Resistance: Excellent performance up to ~1000°C/1832°F.

- Exceptional Corrosion Resistance: Superior resistance to oxidation, sulfidation, and carburization.

- Stabilized Composition: Niobium (Nb) prevents carbide precipitation and improves creep resistance.

- Good Toughness and Ductility: Maintains mechanical properties in as-welded and heat-treated conditions.

- Arc Stability: Smooth arc transfer with minimal spatter.

Performance Benefits

- Self-Lifting Slag: Easy slag removal for efficient welding.

- Positional Welding: Suitable for flat and horizontal positions.

- Thermal Fatigue Resistance: Maintains integrity under cyclic thermal stresses.

- Dissimilar Metal Welding: Effective for joining materials with different thermal expansion coefficients.

Common Applications

- Power generation (boilers, turbines)

- Petrochemical facilities (reactors, catalytic crackers)

- Furnace parts and heat treatment equipment

- Heat exchangers and reformer tubes

- Aerospace and thermal processing equipment

Technical Specifications

Chemical Composition

| Element | Percentage |

|---|---|

| Nickel (Ni) | 25-35% (Primary base metal) |

| Chromium (Cr) | 20-25% (Enhances oxidation resistance) |

| Niobium (Nb) | Stabilizing element (prevents carbide precipitation) |

| Manganese (Mn), Silicon (Si) | Minor elements to refine weld properties |

Mechanical Properties

| Property | Value |

|---|---|

| High-Temperature Strength | Up to ~1000°C/1832°F |

| Thermal Fatigue Resistance | Superior performance under cyclic thermal stresses |

| Sulfidation & Carburization Resistance | Excellent in aggressive environments |

| Toughness & Ductility | Good in both as-welded and heat-treated conditions |

Welding Parameters

| Parameter | Value |

|---|---|

| Preheat/Interpass Temperature | 150–250°C (302–482°F) |

| Post-Weld Heat Treatment (PWHT) | Optional, depending on application requirements |

| Welding Positions | Flat and horizontal (typical for SMAW electrodes) |

Compliance & Safety

- Meets international standards such as AWS A5.11 (for nickel-alloy electrodes)

- Safety Precautions: Use adequate ventilation to avoid inhalation of fumes containing nickel and chromium compounds

- Store in dry conditions to prevent moisture absorption (use a rod oven if required)

Why Choose TOKO 2535Nb Welding Rods?

- Proven Reliability: Trusted in critical high-temperature applications.

- Balanced Composition: Optimized for crack-free welds in aggressive environments.

- Controlled Arc Behavior: Ensures consistent, high-quality welds.

- Global Compliance: Meets international standards for nickel-alloy welding.