What's advantages from TOKO cut-to-length Line?

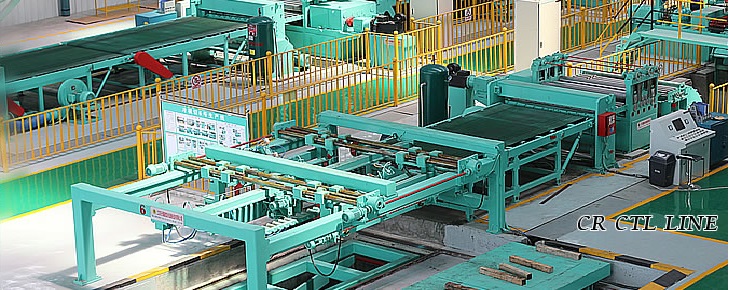

Cut to Length Line (CTL Line) is an automated industrial production system designed to process metal coils (steel, aluminum, stainless steel, etc.) into flat sheets or plates of precise lengths. It is widely used in metal fabrication industries to achieve high efficiency, accuracy, and consistency in producing finished sheets for downstream applications.

Key Components & Functions

-

✅Decoiler:

- ✔Unwinds and feeds the master coil into the production line.

- ✔Equipped with tension control to ensure smooth material flow.

-

✅Leveling/Flattening Unit:

- ✔Removes coil curvature and distortions using multi-roller levelers.

- ✔Ensures flatness for precise cutting.

-

✅Feeding System:

- ✔Advanced servo-driven rollers advance the material to the shear.

- ✔Features length measurement sensors for accuracy.

-

✅Shearing/Cutting Unit:

- ✔High-speed hydraulic or mechanical shear cuts the metal to specified lengths.

- ✔Tolerances as tight as ±0.5mm (depending on material and thickness).

-

✅Stacking/Palletizing System:

- ✔Automatically stacks cut sheets in uniform piles.

- ✔May include robotic arms for palletizing.

-

✅CNC Control Panel:

- ✔Allows operators to input parameters (length, quantity, speed).

- ✔Monitors real-time production data and diagnostics.

Technical Specifications

-

✅Material Thickness: 0.3mm – 6.0mm

-

✅Max Coil Width: Up to 2,500mm

-

✅Cutting Speed: 20–100 cuts/minute (depending on material)

-

✅Sheet Length Range: 500mm – 6,000mm

-

✅Accuracy: ±0.1mm to ±0.5mm

Applications

-

✔Automotive body panels

-

✔Appliance manufacturing (refrigerators, washing machines)

-

✔Construction materials (roofing, cladding)

-

✔HVAC components

-

✔Packaging and container production

Advantages

✅ High Precision: Laser sensors and CNC

controls ensure exact dimensions.

✅ Efficiency: Fully automated operation

reduces labor costs and material waste.

✅ Versatility: Handles various materials

(cold-rolled steel, galvanized steel, aluminum).

✅ Quick Changeover: Digital adjustments

for different sheet lengths and thicknesses.

✅ Quality Assurance: Integrated inspection

systems detect defects (e.g., burrs, warping).

Why Choose TOKO’s CTL Line?

-

✔Smart Manufacturing: IoT-enabled for predictive maintenance and remote monitoring.

-

✔Energy-Saving Design: Optimized power consumption reduces operational costs.

-

✔Customization: Tailored configurations for high-volume or specialty production.

-

✔Certified Quality: Compliant with ISO 9001 and CE standards.

In summary, the advantages of TOKO's Slitting Line stem from its precision, efficiency, versatility, reliability, ease of use, and the comprehensive support offered by the manufacturer.